High Speed Automata Soldering Robotic Arm Programmable Swing Arm Fast Welder Flexible 6 Dof Manipulator Automatic 6 Axis Industrial Robot Arm for Welding

Overview programmable swing arm fast flexible Automatic 6 axis industrial robot arm for welding Product Description Robo

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | HSR-JH605E |

| Certification | ISO, CE |

| Battery Capacity | 2.50kVA |

| Rated Power | 2.00kw |

| I/O Parameter | 32 Pin Input 31 Pin Output |

| Protection Level | IP50 |

| Robot Weight | 196kg |

| Rated Current | 10.8A |

| Repeated Positioning Accuracy | 0.06mm |

| Cable of Electric Cabinet | 3m |

| Cable Length of Teach Pendent | 8m |

| Degree of Freedom | 6 |

| Max. Working Radius | 1441mm |

| Max Load | 5kg |

| Transport Package | Wooden Cases |

| Trademark | HuazhongCNC or HNC or HSR |

| Origin | Wuhan & Chongqing & Guangdong |

| Production Capacity | Based on Site |

Product Description

programmable swing arm fast flexible Automatic 6 axis industrial robot arm for welding

Product Description

Robot welding is the use of mechanized programmable tools (robots) to fully automate the welding process by performing welding and processing parts. It does not require a human operator to prepare the materials to be welded.

Robotic welding is commonly used for resistance spot welding and arc welding in high-volume applications, such as the automotive industry. The many advantages of robotic welding have proven to be a technology that can help many original equipment manufacturers improve accuracy, repeatability, and throughput.

Features

The HSR-JH605E welding robot adopts a hollow structure arm, which is light in weight and compact in structure. This can effectively eliminate the interference between the welding torch cable and the peripheral equipment, and it can be stable and reliable even when working in a small space.

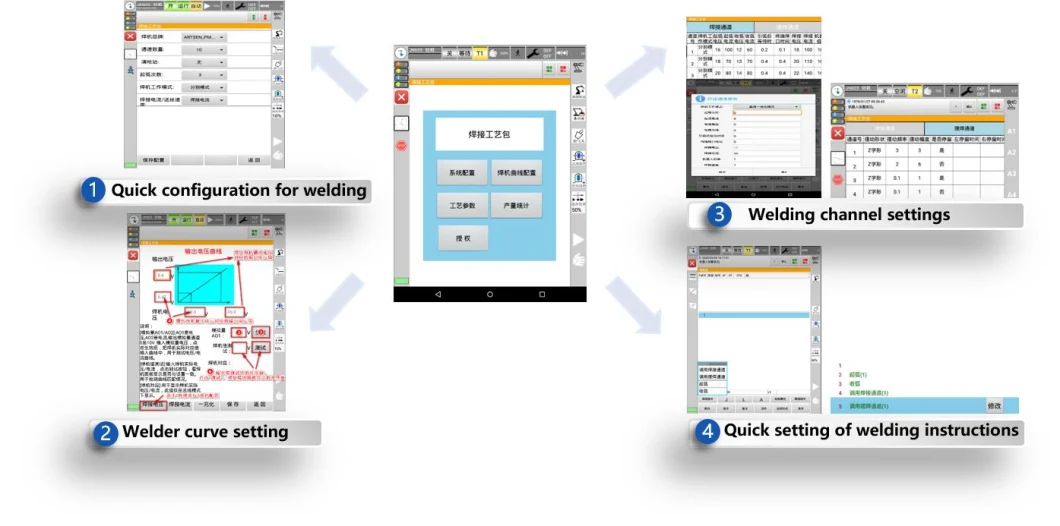

We have integrated a welding solution package specifically for the welding system. It includes various functions such as rapid process deployment of the welding machine, continuous arc welding, intelligent weaving welding, positioner linkage and anti-collision, remote appointment, and collision cancellation.

Axis:6

Payload: 5kg

Arm reach:1441mm

Precision:±0.06mm

Applications: arc welding, spraying, handling...

| Degree of freedom | 6 | |

| Max Load | 5kg | |

| Max. working radius | 1441mm | |

| Repeated positioning accuracy | ±0.06mm | |

| Range of motion | J1 | ±150° |

| J2 | -145°/+60° | |

| J3 | +30°/+270° | |

| J4 | ±120° | |

| J5 | -110°/+140° | |

| J6 | ±360° | |

| Rated speed | J1 | 148°/s,2.58 rad/s |

| J2 | 148°/s,2.58 rad/s | |

| J3 | 148°/s,2.58 rad/s | |

| J4 | 225°/s,3.93 rad/s | |

| J5 | 225°/s,3.93 rad/s | |

| J6 | 225°/s,3.93 rad/s | |

| Max. speed | J1 | 222°/s,3.87rad/s |

| J2 | 222°/s,3.87rad/s | |

| J3 | 222°/s,3.87rad/s | |

| J4 | 337.5°/s,5.89rad/s | |

| J5 | 337.5°/s,5.89rad/s | |

| J6 | 337.5°/s,5.89rad/s | |

| Allowable inertia moment | J4 | 0.30kgm^2 |

| J5 | 0.30kgm^2 | |

| J6 | 0.04kgm^2 | |

| Allowable torque | J4 | 35Nm |

| J5 | 35Nm | |

| J6 | 15Nm | |

| Application environment | Temperature | 0-45° |

| Humidity | 20%-80% | |

| Others | Avoid contact with flammable, explosive or corrosive gas and liquid, and stay away from electronic noise sources (plasma) | |

| Cable length of teach pendent | 8m | |

| Cable of electric cabinet | 3m | |

| I/O parameter | Digital:32 pin input 31 pin output | |

| Battery capacity | 2.50kVA | |

| Rated power | 2.00KW | |

| Rated voltage | Single phase AC220V | |

| Rated current | 10.8A | |

| Protection level | IP50 | |

| Robot weight | 196kg | |

Product Configuration

1.Robot

-Robot body -Cabinet -Teaching pendent2. Welder3. Wire feeder4. Welding gun5. Gas -Mixed:80%AR+20%CO2 -Carbon dioxide:99.9%6. Others -Positioner -Gun cleaning station -etc...Welding Process Package

The welding process package is developed by us, it has multiple functions and a simple interface. You can switch between Chinese and English welding instructions, convenient operation and debugging, easy to use.

Solutions

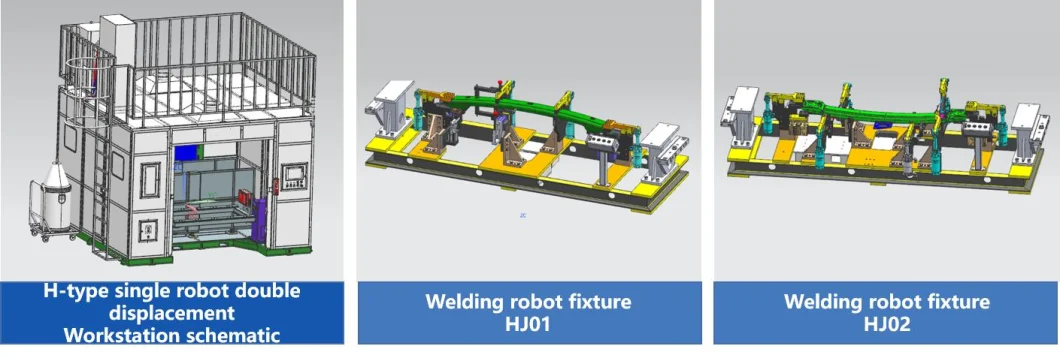

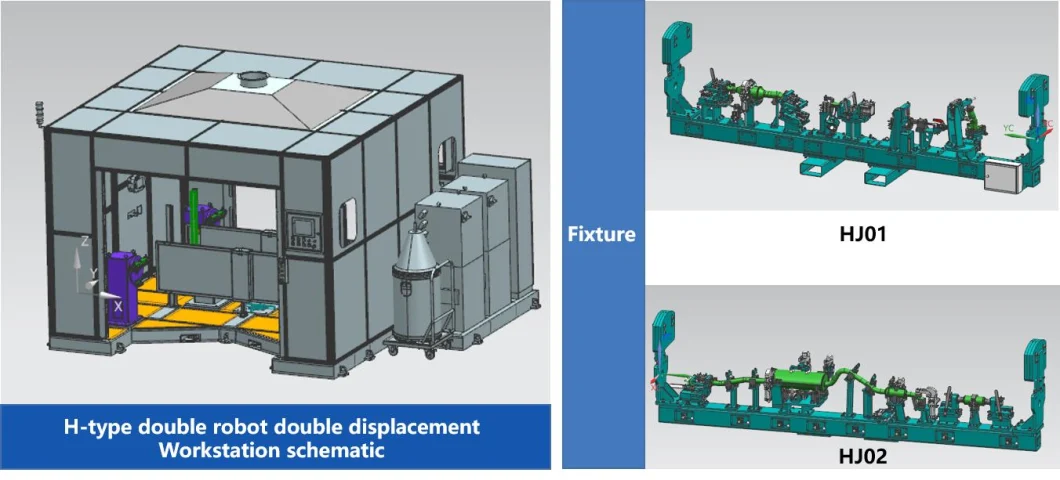

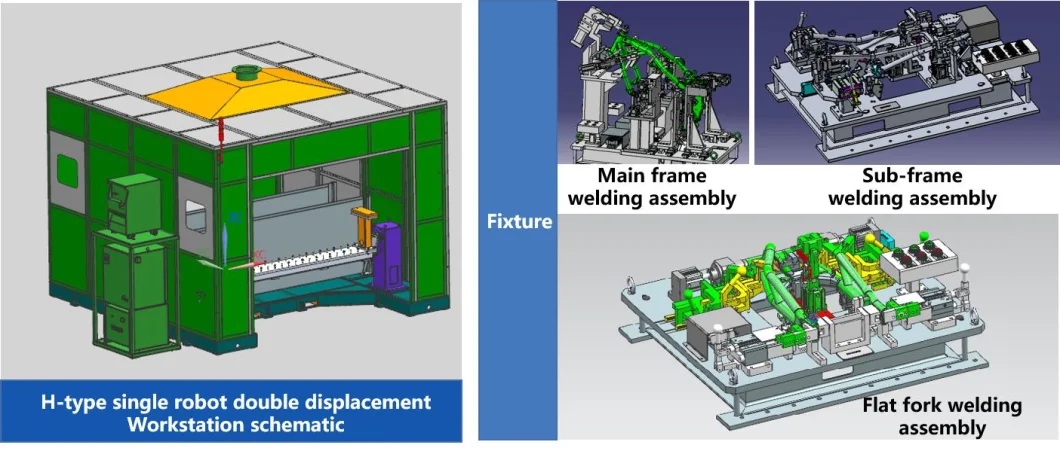

In addition to powerful welding robot products, we also provides a complete set of welding solutions, including welding workstations, welding fixture design, positioners, dust removal systems, gun cleaning stations and other equipment, as well as customized system function development and technical support.

Bumper:

Car Seat:

Silencer:

Motorcycle Frame:

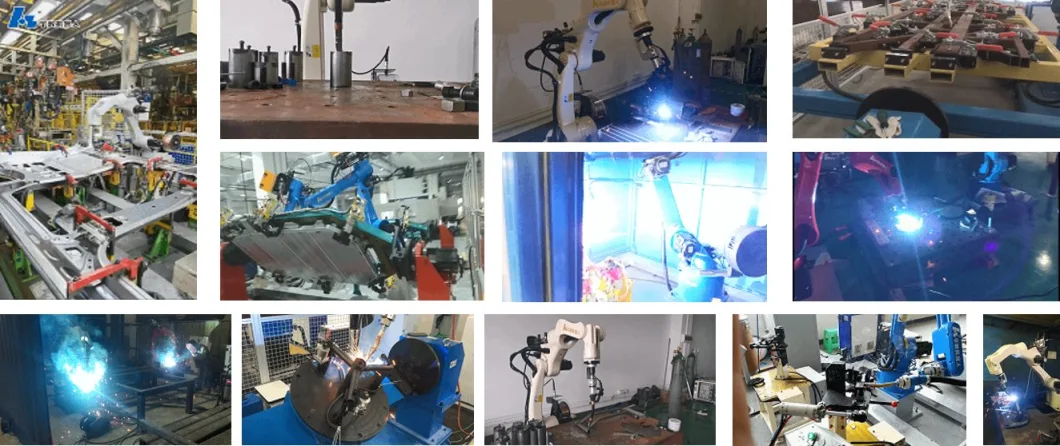

Application Cases

This welding robot has been widely used in automobiles, motorcycles, construction machinery, general machinery, agricultural machinery, hardware, furniture, medical and other industries.

More Products

We also have many other types of indudtrial robots for other application like Load, Pick and place, Move and so on. Contact us to know more.

... ...Contact us to know more!

Related Products

-

![Silicone Rubber Heating Elements for 3D Printer]()

Silicone Rubber Heating Elements for 3D Printer

-

![Modern Mortice Zinc Alloy Door Lock Handle]()

Modern Mortice Zinc Alloy Door Lock Handle

-

![4311991 X15 Qsx15 Rock Lever Cam Follower Lever Blet Tensioner Water Pump Turbocharger Push Rod Starting Motor Alternator Cylinder Sensor Lever for Cummins]()

4311991 X15 Qsx15 Rock Lever Cam Follower Lever Blet Tensioner Water Pump Turbocharger Push Rod Starting Motor Alternator Cylinder Sensor Lever for Cummins

-

![Knobs Handle Screw Clamping Nut Thread End Black Thumb Plastic Knob]()

Knobs Handle Screw Clamping Nut Thread End Black Thumb Plastic Knob